SIPOC is a renowned acronym used in the Six Sigma methodology. It is one of the oldest and trusted tools in Six Sigma which was introduced in the second half of the 20th century. SIPOC is one of the top-level process mapping techniques that is applied before taking up Six Sigma projects. Various stakeholders benefit from such knowledge of the processes designed for a particular project. Moreover, the SIPOC diagram technique helps determine the relationship between various elements involved in satisfying customer needs.

Jump ahead to

What is the SIPOC Diagram?

SIPOC stands for Suppliers, Inputs, Process, Outputs, and Customers. The SIPOC diagram is a flowchart that represents the elements of SIPOC. Each process is matched against these elements for improvement before the project is undertaken. The SIPOC diagram helps in understanding each process from start to end prior to the implementation stage. Process management teams apply the SIPOC model to determine the suppliers of the process, requirements to the process, steps involved in the functioning of the process, expected results of the process, and the consumer who received the results.

Elements of SIPOC

Supplier: Every project needs to source its requirements from different entities. A supplier becomes the person who is providing these requirements to the organization. On identifying the suppliers, the first step of process mapping is complete.

Inputs: In this stage, the process management team gathers the inputs that can be sourced from the supplier. These inputs play a vital role in the whole process as they affect the outcomes of the Six Sigma project undertaken.

Process: This step describes the different stages involved in converting the inputs into outputs. Describing the steps helps the process team to understand the various activities that have to be performed.

Outputs: The outputs refer to the end results of the process. The outcomes can be in the form of products or services depending on the Six Sigma project undertaken. Moreover, the process team needs to ensure that the expected outcomes meet the customer’s needs.

Customer: The outcomes of a process delivered to the end-users or customers. It is a very crucial role for the process team to determine who the target customers of each process designed for the project.

Examples of SIPOC Diagram

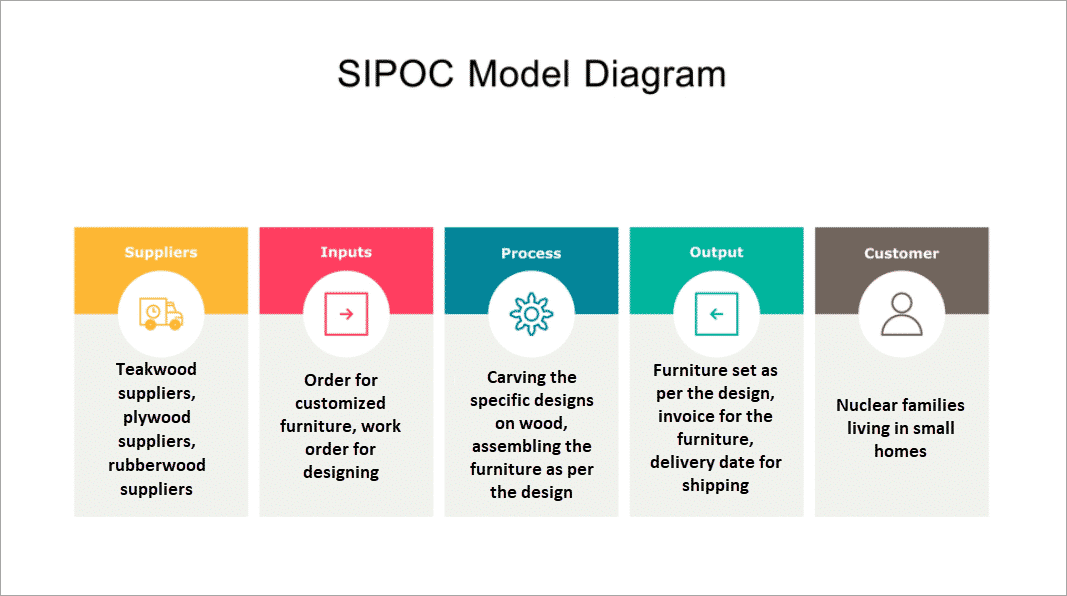

Here is the SIPOC diagram for the furniture manufacturing facility

Suppliers: Teakwood suppliers, plywood suppliers, rubberwood suppliers

Inputs: Order for customized furniture, work order for designing

Process: Carving the specific designs on wood, assembling the furniture as per the design

Outputs: Furniture set as per the design, invoice for the furniture, delivery date for shipping

Customer: Nuclear families living in small homes

The process management teams uses above-mentioned SIPOC diagram for sharing it with stakeholders. The stakeholders then evaluate the process and further improvise if needed. The approved process is then applied by the team while taking up the project.

What are the benefits of the SIPOC diagram?

The SIPOC diagram is graphically represented making it easier to be understood. It offers a complete picture of each process. It helps in identifying the problems and taking measures to improve the process. In addition, the elements of SIPOC provide insights into how the process can be modified to meet customer requirements. Let us have a look at the major benefits of the SIPOC diagram.

Increased transparency

The SIPOC diagram provides a clear, concise high-level overview of a process. This clarity allows team members, stakeholders, or management, to easily understand the components of the process. It helps process management teams to be transparent with stakeholders. This further representing each process graphically ensures that all the stakeholders are on the same page.

Reduce waste

SIPOC offers an excellent overview of the process at a high level. This helps identify process regions where unnecessary steps. The SIPOC diagram facilitates the identification of redundant data or activities that may occur at various stages of the process. Further, finding this duplication enables more effective resource allocation.

Solve process-related problems

The SIPOC diagram is a useful tool for identifying potential issues, challenges, or gaps in the process that might affect its overall efficacy and efficiency. Professional uses it to resolve the problems arising out of a process. In addition, top management can take immediate action to improve a particular process, thereby enhancing the value of a project.

Improved communication

The SIPOC diagram provides a clear, visual representation of processes. As a result, team members and stakeholders are able to communicate more effectively. The SIPOC diagram aids in defining and identifying the different process stakeholders. In the course of communication and decision-making, this guarantees that all pertinent stakeholders recognized and taken into account.

Conclusion

Several organizations are applying the traditional tool of the SIPOC diagram for process improvement. Applying this Six Sigma tool requires individuals to be certified with Six Sigma certifications. So, organizations look for professionals who own the certification in Six Sigma to enhance their efficiency and profitability. There are different levels of Six Sigma certifications such as Six Sigma Yellow belt, Green belt, and Black belt. Individuals can take up either of these certifications while pursuing a career in quality management. Additionally, these certifications are internationally recognized, enabling professionals to land their dream jobs and earn higher salary packages.