Why is Six Sigma important for business? This may seem like an ignorant question, but to people who don’t know what Six Sigma is, it is a perfectly good question. If there is a way to prevent a disease that runs in a family, people will likely do whatever it takes to prevent getting the disease. In business, failure is cancer that lurks, and Six Sigma prevents many little cancers in the business from spreading.

Jump ahead to

What Is Six Sigma?

Six Sigma is a methodology that offers organizations tools and techniques to increase the capabilities of their business processes. This improves performance and reduces process variance, which aids in defect reduction and the enhancement of profitability, employee morale, and product or service quality.

Importance of six sigma in the business

- Six Sigma methodologies strive for perfection, or as close as possible, which is 3.4 defects per million. The methodologies focus on many things, from skillful judgment to the quality of the product, and the processes that deliver them.

- The methodology revolves around disciplined and data-driven practices. It achieves the objectives by employing a variety of statistical and empirical techniques. Every project adheres to a series of well-defined steps aimed at reaching specific value targets. Some of the intended targets include improving customer satisfaction, minimizing operating costs, reducing pollution, boosting profits, and reducing cycle time.

- Six Sigma can provide a quantitative description of how a business or manufacturing process is performing. The description comes in the form of a statistical representation. In order to attain Six Sigma, a process must produce less than 3.4 defects per one million opportunities.

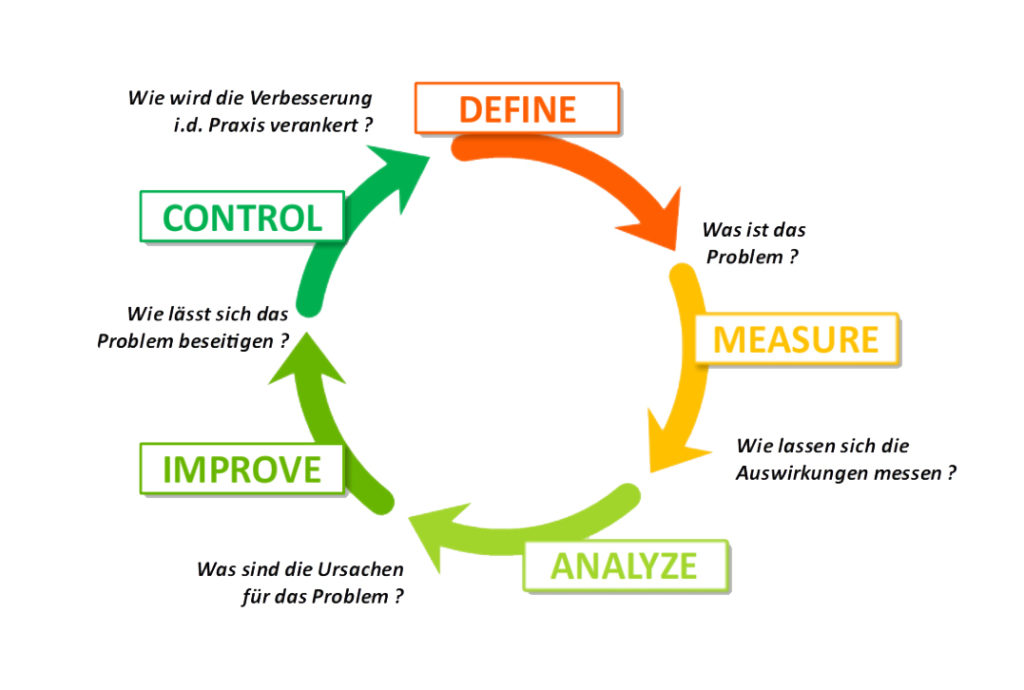

- The implementation of a measurement-based strategy is accomplished using two sub-methodologies: DMADV and DMAIC. The Six Sigma DMAIC stands for define, measure, analyze, improve, and control. This sub-methodology is used to rectify under-performing processes. DMADV, on the other hand, stands for define, measure, analyze, design, verify. It provides a practical way to develop new products or processes at Six Sigma quality levels.

Six Sigma Implementation Roles

The Six Sigma methodologies take quality management from production floors to various levels in an organization. It identifies six principal roles that help ensure successful implementation.

Executive Leadership

Executive Leadership incorporates top-level management. It comprises the leaders that communicate, lead, and direct the company’s overall objectives toward an effective strategy for implementing the methodology. The Chief Executive Officer (CEO) and board members define roles for personnel at various levels. The directives aim at empowering the staff to explore innovative ideas. Staff members are expected to propose breakthrough improvements. The approach breaks down departmental barriers and overcomes resistance to change.

Champions

Champions or sponsors consist of innovators drawn from upper management. They identify and select projects to work on and ensure the availability of resources and resolve cross-functional issues. Champions mentor personnel at lower levels, including the Black Belts. They remove roadblocks that could hinder process success including resistance from employees to changes, and any factors that prevent a project from realizing timely financial benefits.

Master black belts

Master Black Belt role players are appointed by the Champions to act as in-house coaches. Daily duties for members are to focus entirely on the implementation of Six Sigma. They guide personnel on lower levels with the assistance of the Champions. Some of the key roles for Master Black Belts include ensuring consistency across the entire organization and handling statistical tasks.

Black belts

Black belts are responsible for leading and implementing Six Sigma methodology on priority projects which are assigned by Champions and Master Black Belts. They provide special leadership on project-specific tasks to ensure successful execution. Furthermore, they update and present project progress to the management and review the completed projects. Black belt professionals usually work on six to seven projects in a year that have high financial returns to the organization.

Green Belts

Green belts are Six Sigma practitioners who manage Six Sigma implementation as part of their everyday tasks. They have the fundamental skills but less experience than black belts. Green belts have proficiency with statistical tools and use them for positive financial impact and customer benefits. Under the supervision and guidance of a Black belt, they lead two small-scale projects every year.

Yellow belts

Yellow belts have an understanding of the principles and improvement methods of Six Sigma and have the ability to incorporate these approaches into an organization’s production process. They use appropriate tools to address project challenges and implement six sigma concepts in the project. Moreover, they participate and support green and black belt projects.

Organizations often provide specialized training to personnel assigned to Six Sigma roles. This is aimed at ensuring that implementation is done correctly.

DMAIC Process

The implementation of all of the following methodologies is known as DMAIC, which stands for Define, Measure, Analyze, Improve and Control.

Define the problem, goal, or reason the issue needs to be resolved.

Measure the process performance using the current state of the business as a baseline

Analyze the process to determine the root causes of variation and poor performance

Improve the process performance by identifying some creative solutions to get rid of the root causes of the problem.

Control and maintain improved processes to sustain its success.

Final thought

The mindset of constant improvement is also at the core of Six Sigma implementation. If a company wants to have a long and rich existence free of failure, the key is to prevent and solve the problems when they are small and manageable. So in reality, all businesses need to stay healthy, and that is why Six Sigma is important to all businesses big and small.

Aspiring quality management and process improvement professionals can attend the Lean Six Sigma Black Belt, Lean Six Sigma Green Belt, and Lean Six Sigma Yellow Belt Certification Trainings to gain an in-depth understanding of six sigma methodologies to manage projects in an organization.

Unichrone specializes in providing Quality Management certification training courses such as Lean Six Sigma Green Belt, Lean Six Sigma black Belt, Lean Six Sigma yellow Belt. If you would like to know more about the benefits of Quality Management certifications for your career, call our consultant now on: 9886140602 Or email : support@unichrone.com