Jump ahead to

Quality Management Methodologies

Organizations are constantly trying to add value to their business processes and improve the “quality” of their product and services. This mindset has made quality management indispensable in every industry across the globe.

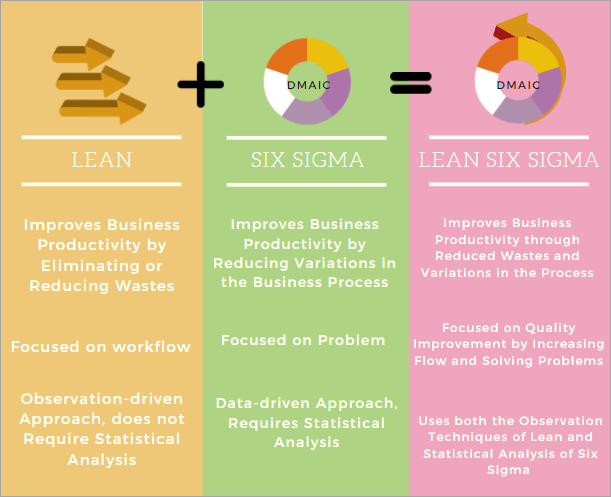

Lean and Six Sigma are well-known quality management methodologies that help organizations deliver quality products and services to their customers. The main objective of both methodologies is value addition.

Lean Vs. Six Sigma – Even though the two disciplines serve the same purpose, there is a difference between lean and six Sigma. They differ in their approaches to achieving their objective. Understanding the essential difference between Lean and Six Sigma is very important. This will, in turn, help in understanding the concept of Lean Six Sigma, which combines Lean and Six Sigma to form a powerful methodology.

Overview of Lean

The Lean methodology focuses on the elimination of waste. It helps improve the business process by reducing wasteful processes that do not add value to the end products or services. This concept was first introduced in the manufacturing industry, which proved effective in increasing business efficiency. Slowly the methodology was introduced in other industrial sectors as well.

Lean defines waste as anything that affects the result and does not meet the customer’s requirements. These wastes can be eliminated or reduced to improve the business’s overall productivity. There are 8 types of waste in the Lean methodology, they are:

- Defects – Products or services that do not meet the organization’s and its customers’ standards.

- Overproduction – Sometimes, more products or services are created unnecessarily, which adds to the overall costs.

- Transportation – Shipping or transportation of products also adds to the budget.

- Over Processing – Some products are subjected to more processing than needed.

- Waiting time – This is the time taken during several processes in the organization.

- Inventory – This includes a surplus of raw materials or finished products.

- Motion – Movement of resources or products without any reason.

- Non-Utilized Talent – Not using human resources effectively or assigning the wrong person to a particular task is also a waste.

The main purpose of the Lean methodology is to maximize business efficiency by eliminating or reducing wasteful processes. This results in delivering quality products and services to the customers. Ultimately, customers pay for products or services that satisfy their requirements without additional costs. Thus, helping organizations increase their productivity and profits.

Introduction to Six Sigma

Six Sigma emphasizes reducing the variation in business processes through statistical analysis. This helps in controlling the process and eliminates the chances of defects. It is a data-driven approach to meet the customers’ requirements. The Six Sigma methodology aims to improve the efficiency of the business process and deliver quality products to the customers.

The methodology of Six Sigma uses the DMAIC method to reduce variation and improve the entire business process. The DMAIC method defines, measures, analyzes, improves, and controls. The 5 phases form an important part of the Six Sigma discipline and find their uses in the Lean methodology. They are discussed in detail below:

- Define – The goal is to define the problem in the process, project, and customer requirements.

- Measure – In this phase, the performance of the process is measured against the process requirements.

- Analyze – After measuring the current state of the process, the problem or defect is analyzed.

- Improve – This phase focuses on improving the process by reducing or eliminating the root causes affecting them.

- Control – The last step in the DMAIC method focuses on maintaining the improvement procedure at its present state.

The Six Sigma methodology of process improvement values customer satisfaction. When the customers get what they want, revenue increases for the organization. Thereby leading to an increase in overall productivity i.e., six Sigma can also transform business productivity. Like Lean, Six Sigma became popular in the manufacturing industry. However, it expanded to other industries and found its application in all aspects of a business process.

Lean vs. Six Sigma

The two-process improvement methodologies of Lean and Six Sigma help organizations achieve the desired goals. Even though their approaches may be different, they serve the same objective. Lean and Six Sigma are often confused to mean the same. Lean vs. Six Sigma means they are two different methods that can be used complementarily for process improvement. This leads to the merging of the two disciplines of process and quality management to become Lean Six Sigma.

Therefore, the main difference between Lean and Six Sigma is that the Lean methodology focuses on waste reduction or elimination, while the methodology of Six Sigma emphasizes producing consistent results.

However, both quality management methodologies have the same objective: process improvement and meeting customers’ requirements.

Importance of Lean Six Sigma

Any business enterprise aims to maximize its processes to attain the desired results. Both Lean and Six Sigma can serve the purpose effectively. Lean six sigma help organizations streamline their business processes and add value to the end products or services. Since both methodologies have their benefits, merging and using both methodologies is a better approach and has a better chance of producing the optimum output.

Lean Six Sigma has been used in organizations across major industries like manufacturing, packaging, supply chain, healthcare, pharmaceuticals, engineering, IT, finance, and many more. Organizations rely on qualified and experienced professionals who understand Lean Six Sigma and its various tools and techniques. These professionals can help them attain the business objectives by successfully implementing Lean thinking and Six Sigma principles.

Unichrone offers Lean Six Sigma Certification Courses to individuals who want to work in the process improvement and quality management sector. The training and certification courses in Lean Six Sigma Yellow Belt, Lean Six Sigma Green Belt, and Lean Six Sigma Black Belt provided are recognized across the industry. Completing and earning the certifications will help professionals become respected quality improvement experts in the industry.

Conclusion

Ultimately, we can conclude that both Lean and Six Sigma are very important for improving business efficiency and increasing productivity. There is no competition between either methodology. They serve the same purpose and have different approaches to attaining the purpose. Organizations implementing the two disciplines as – the Lean Six Sigma methodology produce effective results and will have better success rates. Also, individuals who aspire to become process improvement specialists in their organizations will benefit greatly by understanding the methodology of Lean Six Sigma in detail.