Quality Management is gaining the utmost importance in the present era. Organizations are not willing to compromise on quality while delivering projects to clients. With the advancement in various quality management methodologies, organizations prefer to combine six Sigma and lean methodology to form Lean Six Sigma Principles to improve their projects and services. Initially designed to assist businesses in implementing quality control, six Sigma has positively impacted several large enterprises and organizations in streamlining project quality.

Jump ahead to

What is Six Sigma?

Six Sigma is a quality method through which businesses can improve their processes. This, in turn, increases the performance of the project. When the processes are well controlled, the business has applied the Six Sigma methodology efficiently. Emphasizing quality helps businesses reduce the number of defects arising from the project. The lesser the variation in the deliverables, the higher the quality of the project or service. While six Sigma helps control the processes, the lean methodology helps mitigate the wastages altogether. Integrating both methodologies led to the birth of Lean Six Sigma.

What is Lean Six Sigma?

Lean Six Sigma is based on facts and data that assist in preventing defects. This methodology combines the tools of six Sigma and lean manufacturing. Merging both lean and six Sigma helps to reduce the waste of allocated resources along with the time and effort of employees. It is believed that Lean Six Sigma first originated in the United States Lean Six Sigma in the 1980s. Back then, it was merely a combination of management principles and processes that evolved in Japan. A deeper understanding of this method was absorbed by several organizations only after 2002. Today, there are various levels of Lean Six Sigma based on expertise. They are:

- Yellow Belt

- Green Belt

- Black Belt

- Master Black Belt

These levels are awarded as Lean Six Sigma Certification to individuals pursuing their careers in quality management. Each level demonstrates the extent of understanding and knowledge of six sigma concepts. However, the methodology has a standard process, and implementing lean six Sigma has many benefits which improve business processes. The popular DMAIC (Define, Measure, Analyze, Improve, and Control) process is the framework used for emphasizing customers through data and statistical techniques.

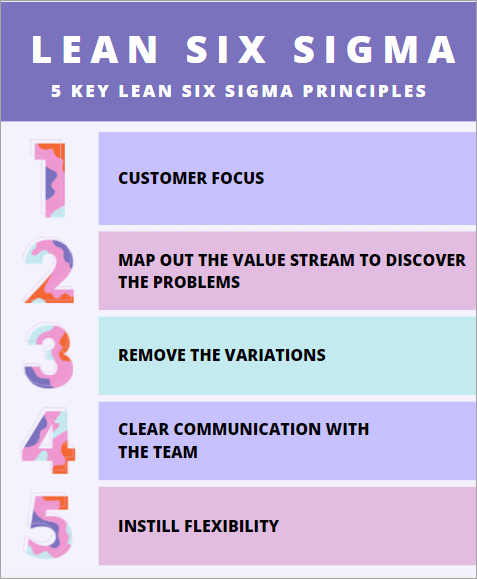

Organizations looking forward to applying the Lean Six Sigma methodology must focus on 5 key principles. These principles assist in achieving desired business efficiency and effectiveness. Let us have a look at these principles.

5 Key Lean Six Sigma Principles –

- Customer Focus:

Often businesses are seen giving more importance to their clients as they hold the organization’s reputation. Lean Six Sigma helps such businesses to understand their customers and their needs. This further assists in establishing a standard level of quality demanded in the market. By delivering projects as per customer needs, businesses can retain their customers.

- Map out the value stream to discover the problems:

This principle of lean six Sigma requires a business to map its processes. On mapping complex processes, activities that do not create value for the customer can be eliminated. To do so, businesses need to gather data to identify the problem area. Businesses need to investigate the root cause of the problem before trying to alter it as per the Lean Six Sigma methodology.

- Remove the variations:

In identifying the problem, businesses are required to determine ways in which variations can be eradicated. A recent study unveiled that variations can occur in long processes required to be carried out for complex projects. Altering or removing such processes through Lean Six Sigma can decrease variations in a project or service. This way, businesses can achieve the desired project quality.

- Clear communication with the team:

The principles of Lean Six Sigma can be applied only when every individual in the project team is well-versed in the methodology. Lean Six Sigma methodology can bring rigorous changes to the organization. As a result, businesses need to concentrate on the impacts of implementing the methodology. Maintaining transparency with all the stakeholders helps reduce project failure’s causes.

- Instill flexibility:

Lean Six Sigma focuses on change, requiring a business to welcome the changes occurring during its implementation. In simple terms, management has to prepare employees to adapt to the changes due to the Lean Six Sigma methodology. This can be done by hiring certified professionals with Black Belt or Green Belt credentials. Such professionals can explain the method’s benefits and how it can improve the workflow. This helps to speed up the transformation process, thereby benefitting the organization.

Conclusion:

Lean Six Sigma principles use the best six Sigma and lean methodologies. Applying these principles during the transformation process helps optimize the project management process. Furthermore, businesses can work towards delivering projects with improved quality and fewer wastages. Individuals involved in the transformation process can master the Lean Six Sigma methodology by taking the Lean Six Sigma Green Belt Certification Training course offered by Unichrone.